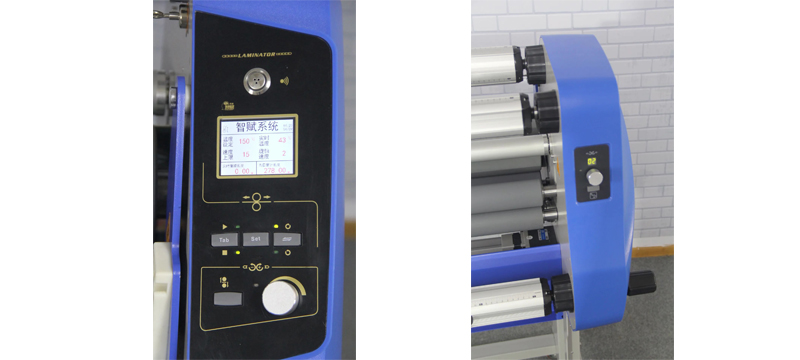

LF1700-D4 laminating and cutting machine is a wide-ranging laminating equipment. The equipment controls the automatic lifting of the roller through the air cylinder. It is simple and practical, and can be cold-laminated at low temperature, automatically peeling the backing paper, and automatically winding. Especially when the cold-laminating film is working, the roller can be properly heated to improve the laminating effect.

Using pulse-type double knobs, the speed can be switched back and forth arbitrarily, which is convenient for fine-tuning and correction of rear cutting. It is resistant to electrostatic shock, and automatically returns to the set startup speed when the lamination stops.

02 Paperless automatic stop

The number of meters of lamination and the number of meters of remaining deceleration can be set to ensure that the speed is automatically reduced and stopped accurately before the high-speed lamination stops. During normal lamination, when the picture triggers the paperless photoelectric, a prompt will appear on the screen, and at the same time, there will be a sound and light alarm, and the machine will stop accurately according to the set length, truly achieving unattended operation. (Patented product)

By adjusting the support wheel and fine-tuning the handle, the to-be-covered picture can be flattened, which can effectively avoid picture folds.

03 Platform rod locking function

The platform round rod can be rotated or not rotated through the locking handle on the right end face, so that it is convenient to choose when covering different materials.

04 Anti-static rope

The anti-static rope is usually placed near the liner paper material bar. The static electricity generated when the liner paper is peeled off will be guided to the anti-static rope, which will be released to minimize the residual static electricity on the material.

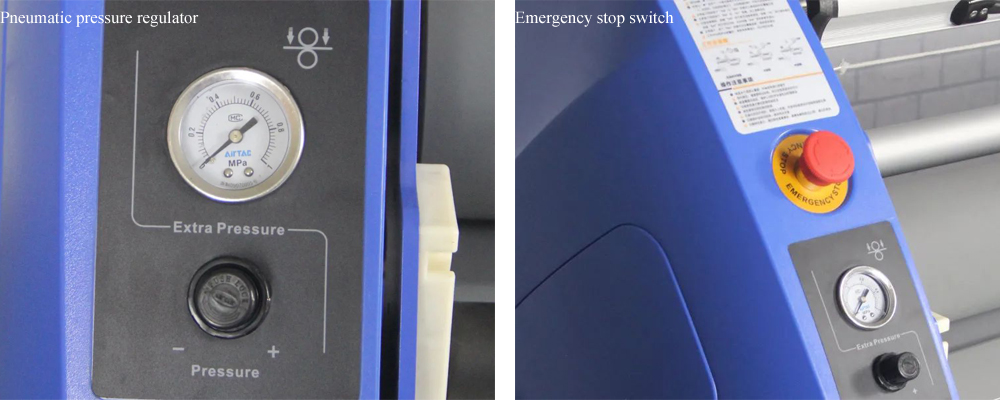

05 Pneumatic pressure regulator

The pneumatic pressure adjustment device consists of a pressure gauge and a pressure adjustment knob.The pressure gauge is used to observe the current air pressure; the pressure adjustment knob can adjust the pressure of the lifting cylinder, thereby increasing or decreasing the pressure of the upper roller.

06 Emergency stop switch

In case of emergency, pressing the red button can immediately cut off the internal power supply, the display screen will be off, and the rubber roller will stop rotating; rotating the red button clockwise will automatically rise, the internal power supply will be turned on again, the display screen will be on, and it will return to the default state of power-on.