The machine is equipped with an oil-water separator to separate the water vapor in the compressed gas, and the excess water is discharged through the water outlet; in order to better protect the cylinder and prolong the service life of the cylinder.

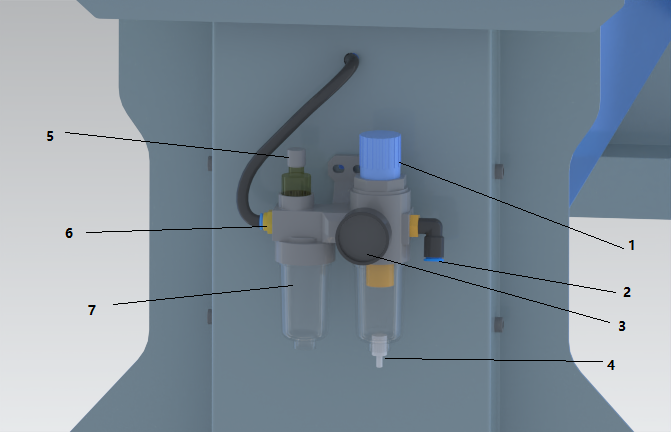

①air pressure adjustment switch ②air inlet φ8(connected to air compressor)③pressure gauge ④water outlet ⑤oil volume adjustment switch ⑥air outlet φ6 (connect to the chassis air tube)⑦oil can

The machine is equipped with an oil-water separator to separate the water vapor in the compressed gas, and the excess water is discharged through the water outlet; in order to better protect the cylinder and prolong the service life of the cylinder, it is recommended to add a little cylinder lubricating oil to reduce the sealing ring of wear. At the same time, the device can adjust the air pressure, the air pressure is generally 0.4-0.5MPa, and the maximum is 0.7MPa.

Note: When adjusting the air pressure, you need to pull up the knob on the outside of the air pressure adjustment switch, turn it clockwise to increase the pressure, and turn it counterclockwise to decrease the pressure. Observe the indication of the pressure gauge. After the adjustment is complete, press the knob down to the original position and lock switch.

Precautions: