The parallelism of the upper and lower rollers has been adjusted before leaving the factory. After using for a period of time, if you find that the deviation is too large, which affects the laminating effect, please check and adjust according to the following steps.

A.Inspection steps:

Open the end caps of the left and right boxes:

Check whether the cylinder support is loose. If it is loose, adjust the cylinder support and tighten it.

Check whether the connecting bolts on both sides are loose, if they are loose, please tighten them.

Check whether the lock nuts on both sides are loose, if they are loose, please tighten them.

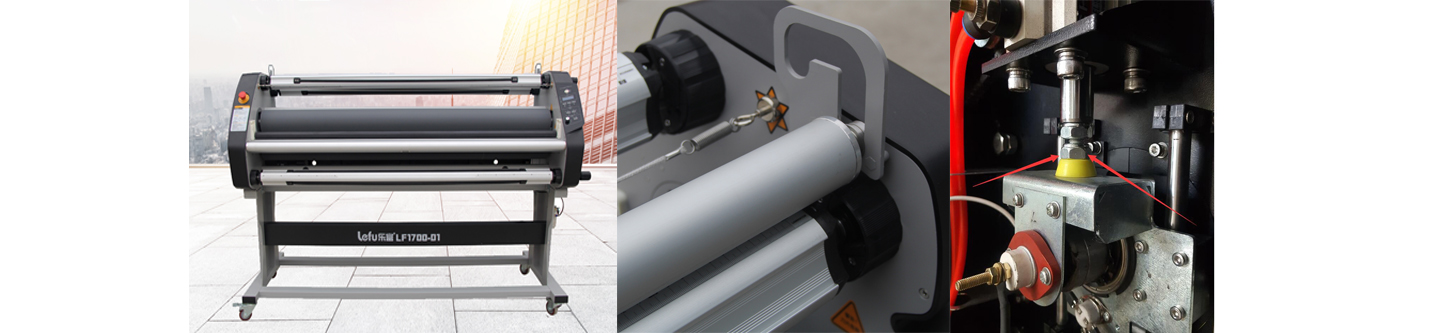

B.How to adjust the parallelism of rollers:

a)Drop the upper roller and turn the ‘adjusting screw’ counterclockwise to leave a 0.5mm gap between the nut and the small beam. Same on both sides

b)Fix the nut of the ‘adjusting screw’ and turn the ‘locking nut’ clockwise upwards to lock it together with the ‘cylinder screw’

c)(Fix the nut of the ‘adjustment screw’ and turn the ‘pressure adjustment nut’ to leave a gap of 2mm between the ‘pressure adjustment nut’ and the ‘compression spring’(It can ensure the roller in a natural downward pressure state)

C.How to adjust the pressure of rollers:

Natural pressure:When leaving the factory, the roller is adjusted according to the state of natural pressure. The natural pressure is the pressure generated by the self-weight of the roller. This pressure is the most even when applied to the material, and the customer is also the easiest to adjust and grasp; the laminating effect is also the best. The thickness of materials less than 2mm are all laminated by natural pressure. If you want to use natural pressure for thicker than 2mm materials, you only need to increase the gap between the ‘pressure adjustment nut’ and the ‘compression spring’.

Artificial pressure:If the natural pressure cannot meet your needs, you need to turn the ‘pressure adjustment nut’ downward to press the ‘compression spring’. The tighter the spring, the greater the pressure on the film. Adjust both sides at the same time, and try several times to make the pressure on both sides the same.