Avoiding bubbles during the lamination process with a flatbed laminator involves several steps to ensure a smooth, professional finish. Here is a comprehensive guide:

Clean the Surface: Ensure that the substrate (the material to be laminated) is clean and free from dust, dirt, and oils. Use a lint-free cloth and an appropriate cleaner to wipe it down thoroughly.

Smooth Surface: Make sure the surface is as smooth as possible. Sand down any rough spots if necessary.

Humidity Control: Maintain a controlled environment with low humidity, as high humidity can cause moisture to get trapped under the laminate, leading to bubbles.

Temperature Stability: Ensure the working environment is at a stable temperature. Extreme temperatures can affect the adhesive properties of the laminate.

Calibrate the Machine: Ensure the laminator is properly calibrated for the material you are using. This includes setting the correct temperature, pressure, and speed.

Check Roller Alignment: Verify that the rollers are clean and properly aligned. Misaligned rollers can cause uneven pressure and result in bubbles.

Even Pressure Application: Apply even pressure across the entire surface to prevent air pockets from forming.

Steady Operation: Operate the laminator at a consistent speed. Moving too quickly can trap air under the laminate.

Smooth Application: Use a squeegee or similar tool to smooth out the laminate as it is applied, working from the center outward to push any air bubbles toward the edges.

Avoid Stretching: Do not stretch the laminate material as it can lift and create bubbles.

Preheat the Substrate: If necessary, preheat the substrate to match the temperature of the laminating film. This can help improve adhesion and reduce the risk of bubbles.

Use Release Paper: Consider using release paper (backing paper) to guide the laminate onto the substrate smoothly.

Reapply Pressure: After lamination, use a roller or squeegee to go over the entire surface again to ensure all bubbles are pushed out and the laminate is firmly adhered.

Inspect the Lamination: Immediately inspect the laminated item for any bubbles. If detected, they can often be smoothed out before the adhesive sets completely.

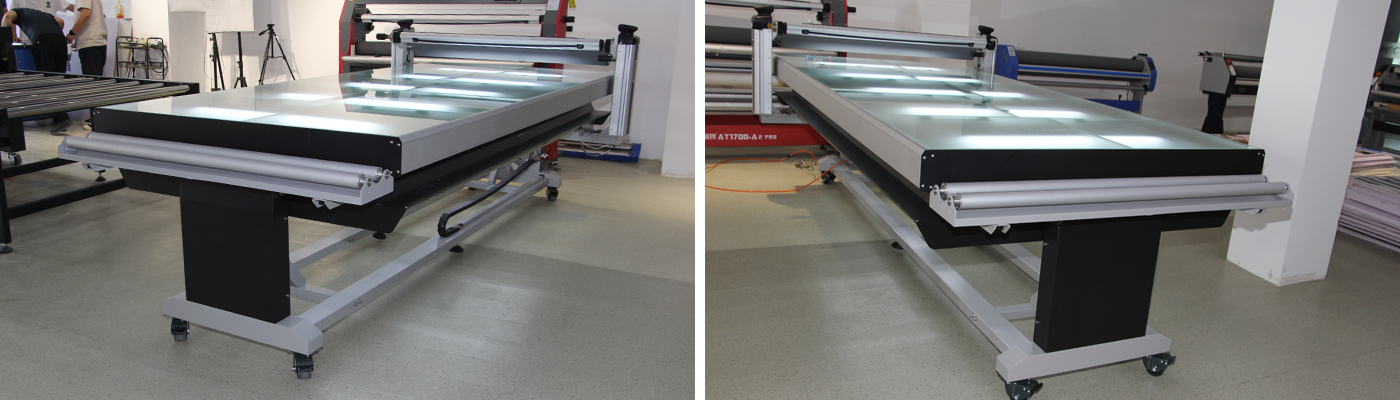

LeFu Flatbed Laminator has 1.3*2.5m (4.26*8.20ft) and 1.6*3.0m (5.24*9.84ft) two size table laminator.

By these detailed steps and paying careful attention to each aspect of the lamination process, you can minimize the occurrence of bubbles and achieve a high-quality, professional finish.