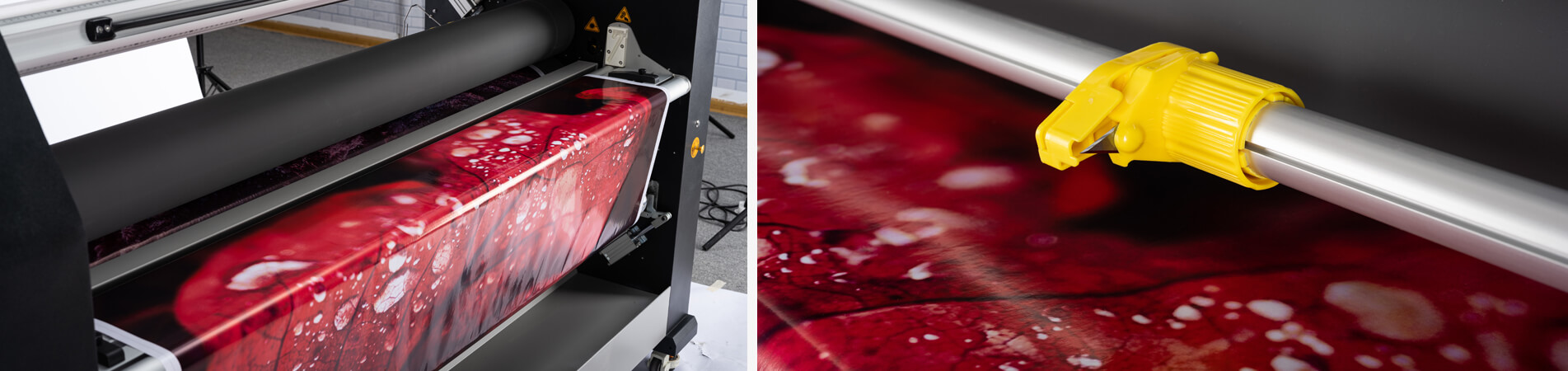

Roll-to-roll lamination is a process used to bond two or more layers of materials together using heat and pressure. Bubbles can occur during this process, which can compromise the quality of the final product. Here are some tips to avoid bubbles during roll-to-roll lamination:

1. Clean the surfaces: Before lamination, make sure that the surfaces to be bonded are clean and free of any dust, dirt, or debris. Any contaminants on the surface can cause bubbles to form.

2. Use the right adhesive: The adhesive used for lamination should be appropriate for the materials being bonded. The adhesive should also be applied evenly to avoid any air pockets.

3. Control the temperature: The temperature of the laminating machine should be controlled carefully. If the temperature is too high, it can cause the adhesive to bubble. If the temperature is too low, the adhesive may not bond properly.

4. Control the pressure: The pressure applied during lamination should also be controlled carefully. Too much pressure can cause the adhesive to spread too thin, while too little pressure can cause air pockets to form.

5. Use a release liner: A release liner can be used to prevent bubbles from forming during lamination. The release liner is placed on top of the adhesive before lamination, and then removed after lamination is complete.

By following these tips, you can avoid bubbles during roll-to-roll lamination and ensure a high-quality final product.

LeFu Laminator (https://www.hotlaminator.cn/) is a leading manufacturer of Automatic Laminator, Roll Laminator, Hot Laminator, Warm Laminator, Cold Laminator, Wide Format Laminator, Flatbed Laminator, Flatbed Applicator in China from year of 2006.